May 9, 2025

A lot of fine tuning the trackwork was a time-consuming job. First of all, the glue in the frogs was checked with a NMRA gauge and filed deeper where necessary. At time a Dremel was used to cut a little deeper before finishing off with a file. Now drops into the frog area has been improved.

A steam loco and a couple of cars ran through all the switches and was great at turning up problems not evident with the heavier diesel. In many instances, the curved point rail needed just a hair more clearance. This should have been done before painting the rail. The paint made it harder to melt the solder. A couple of electrical problems were fixed.

Another 3-way switch was constructed and as soon as I get to the lumber store will start the staging yard.

The fascia for the remaining town was installed. Waiting for sheetrock mud to dry so it can be sanded smooth on joints.

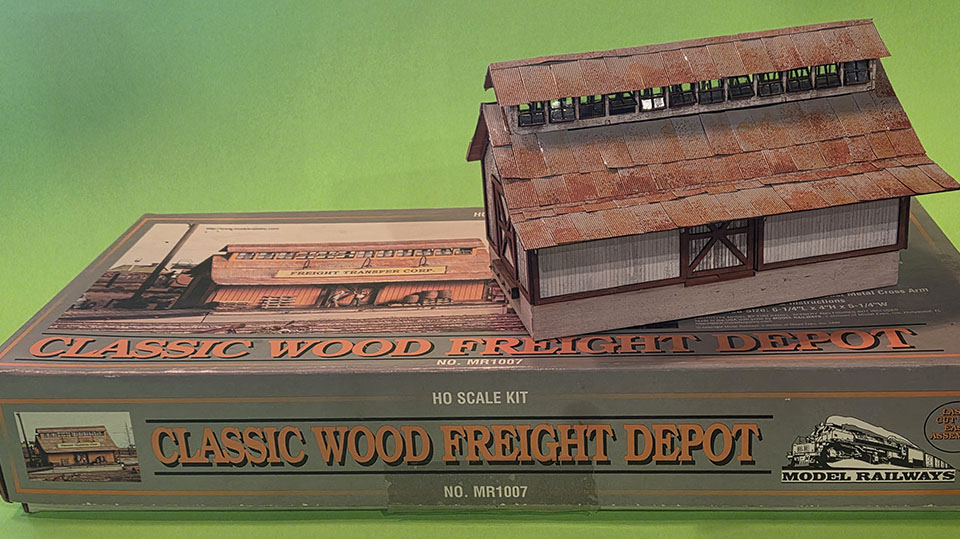

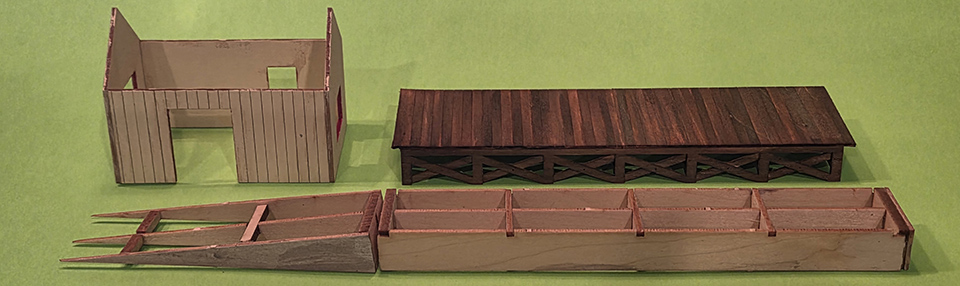

The laser kit from hell was completed. There were many instances where the thickness of the wood was not considered in cutting the kit – decks, roof, and clearstory. Even though I bought the kit new 30 years ago, there were some missing pieces. I’ll be constructing a new deck as all the material was worthless.

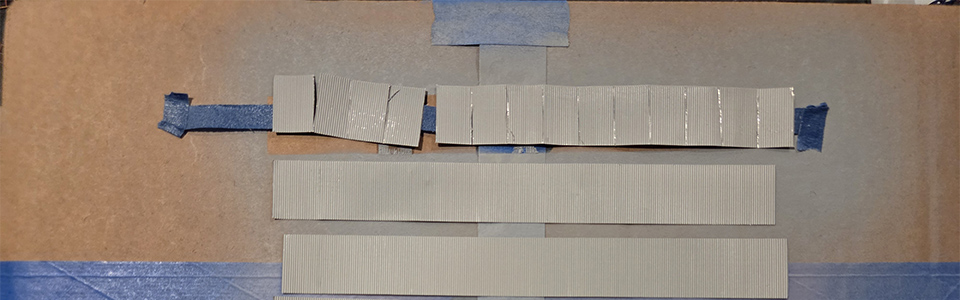

The tin shingles were Campbell cut into 4′ sections after sparying gray. Each long strip was taped before cutting and then cut deep enough to separate the shingles but not so deep as to cut the tape. After cutting, a second spraying helped eliminate any shiny areas (still a few to touch up.) Three varying rust colors were applied with a sponge while still attached to the masking tape and a dusting of Pan Pastels was the finishing tough.

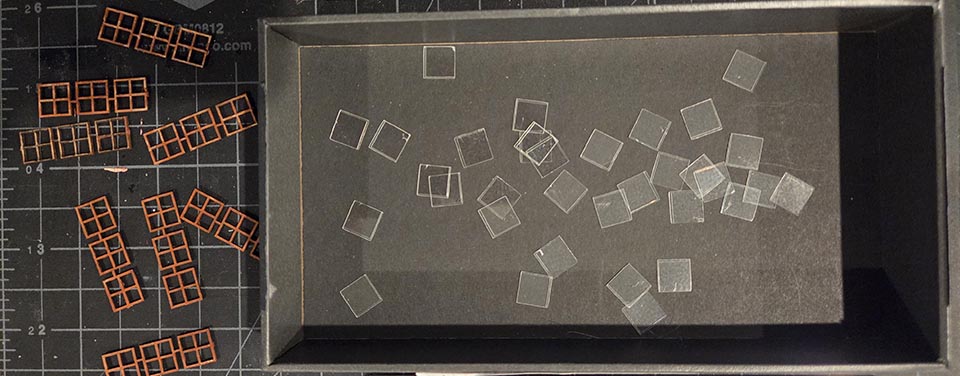

24 panes of window glass was needed so I used my wife’s Circuit. The vinyl setting didn’t cut all the way thru, so a second pass was made using matte board setting. Canopy glue was used to fasten panes to frame.

Tomorrow, we finish the group’s freight house adding trim, roof, and doors. This was the way a kit should be made. Compare framing for previous kit with the beautiful deck that this kit provided. The kit was designed and cut by one of our members – Duane Richardson. Excited to get it done.

WOW! More of a monthly report. Now that so much construction is complete, I think I will continue to add to the blog only monthly.